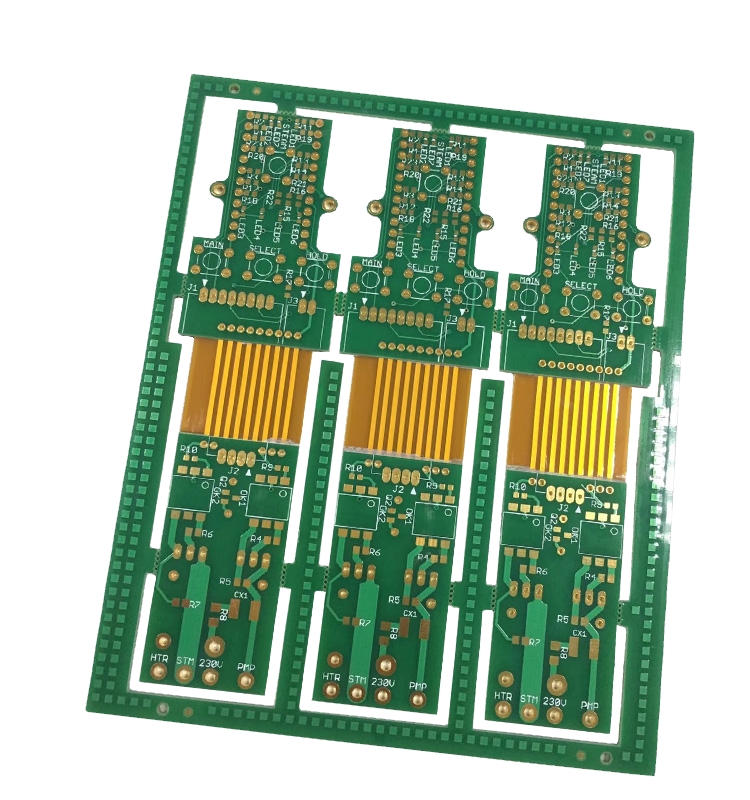

Capabilities Of Rigid Flexible PCB

| Item | Capability |

| Layers | 2-12 Layers |

| Min Track / Spacing | 0.075 mm / 0.075 mm |

| Min Hole Size / Pad Size | 0.10 mm / 0.35 mm |

| Rigid-Flex Thickness | 0.25 mm-6.0 mm |

| Max Copper Thickness | 3 oz |

| Max WPNL Size | 610 mm X 914 mm |

| Finish Copper(Flex Part) | 0.5-2 oz |

| Finish Copper(Rigid Part) | 1-3 oz |

| Max Aspect Ratio | 13:1 |

| Surface Finish |

ENIG、Electric gold、IM-Ag、Electric Ag、HASL、

HASL-LF、IM-Sn、Electric Sn、OSP、Caborn、 PtNI-Pd-AU |

| Drilling Accuracy | +/-0.05 mm |

| PTH Diameter Tolerance | +/-0.05 mm |

| Build time | 7-20 days |

| RFQ | 1-2 days |