Prodution Capacity

The quality of the product is always determined by the quality of the tool. In our factory, quality is paramount. To ensure a consistent production process and reliable product quality, our PCB equipment is sourced from machines that meet high quality standards.

To give you an idea of the PCB equipment used in our state-of-the-art factory, here are some photos of our current equipment.

-

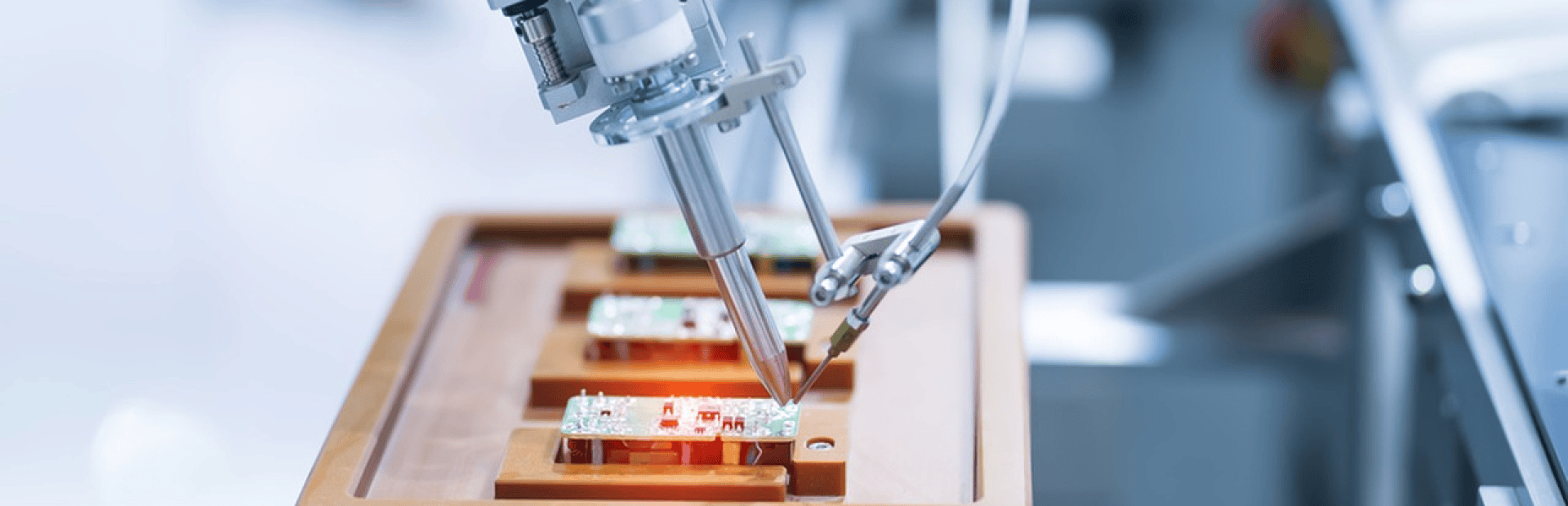

Flying Probe Tester

Flying Probe Tester is an automated system with a small number of probes. It is used to check the integrity of alignments and through-hole interconnections - checking to ensure that there are no open or short circuits on the finished board.

- Lower upfront investment because there are no additional costs associated with fixturing.

- Less programming time for.

- Allows for easy testing of prototypes and small batch runs.

- Is an easy way to detect shorts, opens, missing components, wrong polarity, etc.

- Doesn't require any additional DFM or data messaging effort.

-

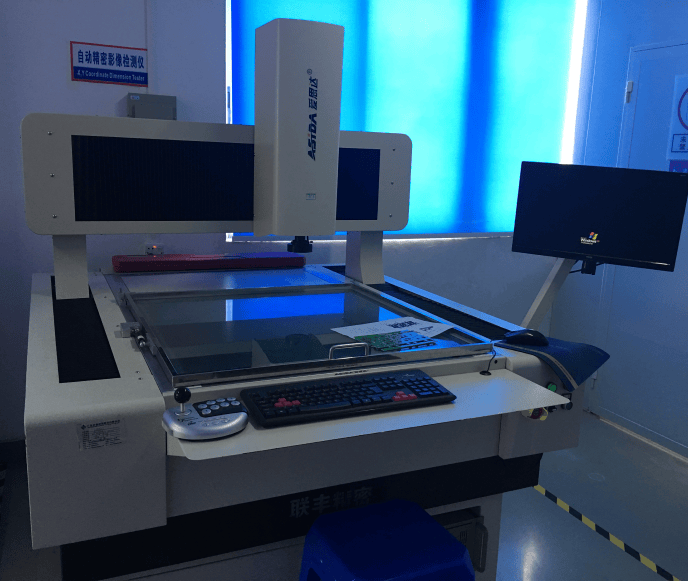

X,Y Coordinate Dimension Tester

X,Y Coordinate Dimension Tester uses an optical microscope to image the object to be measured with free magnification for non-contact, efficient inspection of a variety of complex PCB, and it solves the problem of dimensional measurement of the appearance of PCB.

- Offers high speed and accuracy, and can perform multiple functions on a single machine.

- Has batch automatic measurement and program editing capabilities.

- Includes basic image processing functions, such as deburring and centerline finding.

- Has statistical analysis, auto-focus, auto-detection and other functions.

-

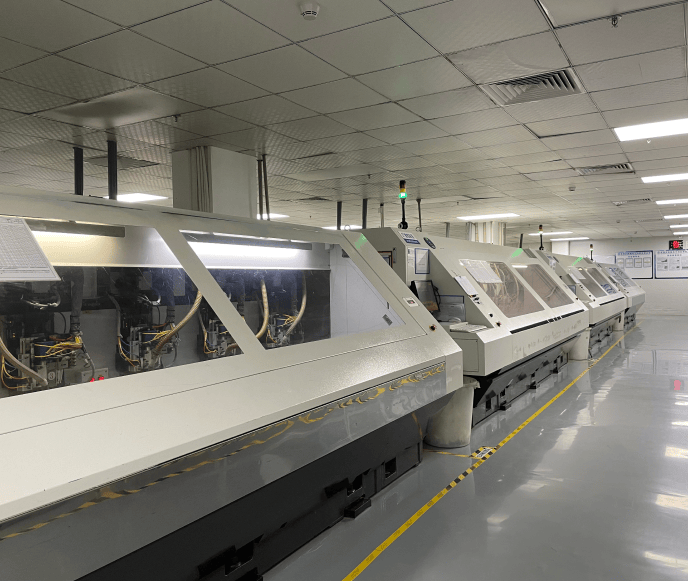

Routing Machine

Routing Machine used for stamp hole connection and irregular PCB board division.

- Is capable of continuous cutting without interruption during loading and unloading.

- It's high quality spindle system allows the system to accelerate and decelerate quickly, increasing productivity while maintaining high accuracy.

- Uses high quality hardware to ensure high steel and high performance.

-

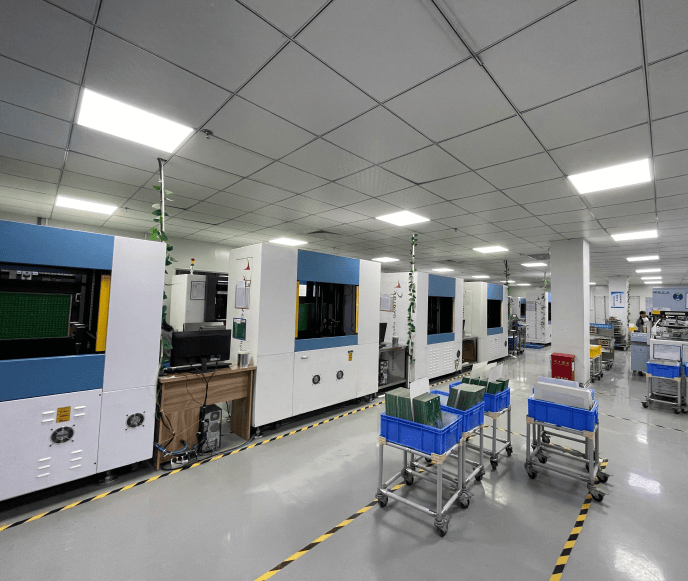

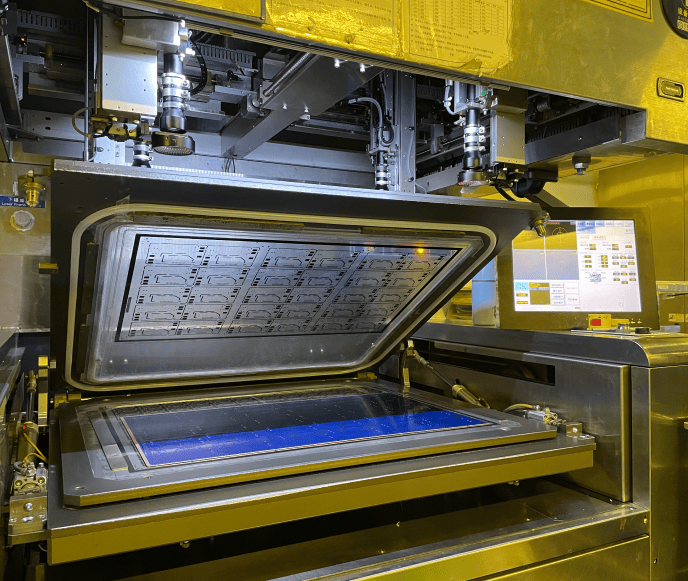

Exposure Machine

Exposure Machine is used to transfer the circuitry to the pcb board. That is, the PCB board is exposed to the circuit diagram part under the cover of the film backing, and after exposure this part is polymerized. In the development process, the unexposed part can be cleaned off using the developer, while the part of the polymerization reaction after exposure can not be cleaned off, so that the circuit on the PCB board is initially formed.

-

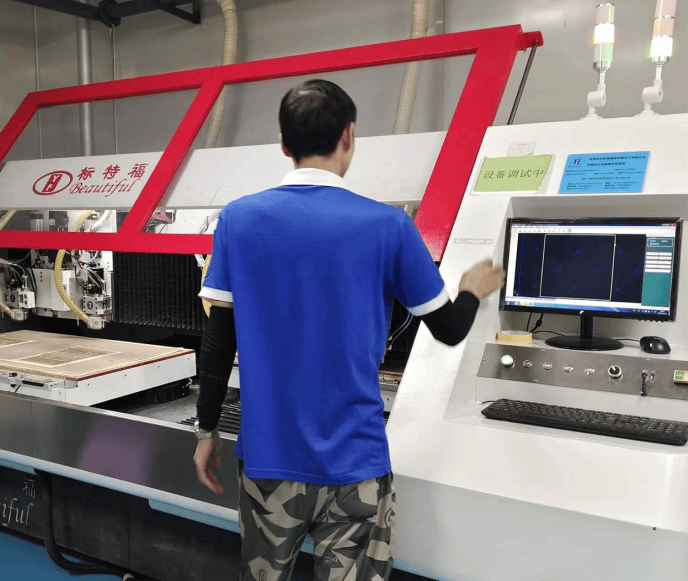

Laser Machine

Laser Machine through the laser beam emitted by the FPC board to absorb, instantly interrupt the molecular chain to achieve the cutting effect of the cold processing process.

- Is equipped with imported lasers, fully sealed optical circuit, to ensure stable and reliable light transmission and excellent laser cutting quality.

- Adopts stable energy picosecond laser, UV and green laser, cold light source, laser cutting heat affected zone is less than 10μm.

- Has professional customized cutting software, is easy and convenient to operate, easy and fast to change material operation.

- The overall structure of equipment is steady and solid, and its one-piece closed structure provides guarantee for high speed, high precision and high yield production.

- Can use CCD for automatic positioning and correction; vacuum adsorption fixed plate, no need for alternative fixture.

-

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI), is based on the optical principle to detect common defects encountered in the production of welding equipment. When automatic inspection, the machine uses high-speed and high-precision vision processing technology to automatically detect a variety of different placement errors and soldering defects on PCB boards.

- Uses a rich set of dedicated multi-functional inspection algorithms and binary or grayscale horizontal optical imaging processing to perform the inspection.

- Performs automatic correction of the inspection window based on instantaneous changes in the position of the inspected components to achieve high accuracy inspection.

- Performs verification of inspection electricity by marking directly on the PCB board with ink or by graphical error representation on the operation display.

-

Drilling Machine

Drilling Machine is used to connect the outer layer circuit with the inner layer circuit. It is based on numerical control technology, and through the coordinated movement of X, Y and Z coordinates, the X and Y axes are controlled to move quickly and accurately to the drilling position, and the Z axis actuator performs the drilling operation to achieve precision drilling processing.