News

Site Editor

Site

/uploads/image/667d0e0257f45.png

Site

/uploads/image/667d0e0257f45.png

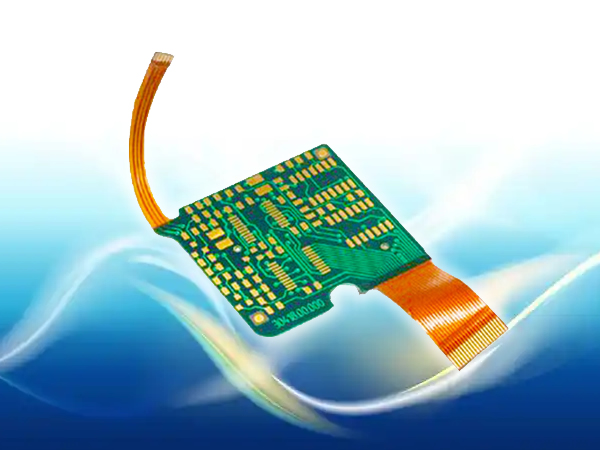

Choosing the Right Materials: Key to Designing the Ideal Flexible PCB

Views: 1349

Author: Site Editor

Publish Time: 2024-12-10

Origin: Site

When designing a flexible

PCB (Printed Circuit Board), selecting the appropriate materials is crucial to ensure its performance, reliability, and durability. This article outlines some key factors and guiding principles to help you choose the best materials for your flexible PCB, ensuring optimal performance across various applications.

Understanding the Characteristics of Flexible PCBs

Flexible PCBs are known for their excellent flexibility and bending capabilities, so material selection should consider the following characteristics:

Flexibility: Choose materials that can withstand repeated bending and flexing, such as polyimide (PI) or polyester (PET).

Thermal Stability: Ensure that the selected materials maintain stability in high-temperature environments to prevent deformation and performance degradation.

Electrical Performance: Prioritize materials with good electrical insulation properties and low dielectric constants to minimize signal transmission interference and loss.

Considering the Application Environment

Flexible PCBs are used in various environmental conditions, so it's essential to consider the following factors:

Temperature Range: Select materials based on the application's temperature requirements to ensure they function effectively within the expected temperature range.

Corrosion Resistance: For humid, corrosive, or chemically aggressive environments, choose materials with corrosion resistance or use protective coatings.

Dust and Water Resistance: In applications requiring dust and water protection, select materials with these properties or implement additional protective measures.

Substrate Strength: Ensure that the chosen materials have sufficient tensile and tear strength to withstand external stress and deformation.

Stiffener Materials: In areas requiring extra support, such as connection points or component mounting regions, consider adding stiffener materials to increase mechanical strength.

Processability of Materials

When selecting materials, consider their processability to meet design requirements:

Thinness and Lamination Capability: Choose the appropriate material thickness and lamination capability based on application needs to meet the required circuit layers and flexibility.

Copper Foil Adhesion: Ensure that the selected materials bond well with copper foil to provide good electrical connections and reliability.

Choosing the right materials is a critical step in designing a flexible PCB. Understanding the characteristics of flexible PCBs, considering the application environment, and focusing on the mechanical strength and processability of materials will help ensure the reliability, performance, and durability of your flexible PCB. By carefully considering these factors and conducting experimental validation, you can select the best materials to create a high-performance flexible PCB.