Flexible Printed Circuit Boards (PCBs) have revolutionized the electronics industry with their ability to bend, twist, and conform to various shapes and sizes. These circuits are made from flexible substrate materials, such as polyimide or polyester, which offer superior flexibility compared to traditional rigid PCBs. In this article, we will explore the manufacturing processes involved in creating flexible PCB circuits, discuss their benefits, and highlight the challenges associated with their implementation.

Substrate Preparation:The manufacturing process of flexible PCB circuits begins with the preparation of the substrate material. This involves cleaning the substrate and applying an adhesive to ensure proper bonding of the copper traces.

Copper Cladding:After substrate preparation, a thin layer of copper is laminated onto the substrate using heat and pressure. This copper layer forms the conductive pathways of the flexible PCB circuit.

Circuit Imaging:The circuit pattern is then transferred onto the copper-clad substrate using a process called imaging. This involves applying a photosensitive material, exposing it to UV light through a mask, and developing it to create the desired circuit pattern.

Etching:The exposed copper is then chemically etched away, leaving behind the desired circuit traces. This process is critical in defining the conductive pathways and connections on the flexible PCB.

Plating:Plating is performed to enhance the durability and conductivity of the circuit traces. Through a process called electroplating, a thin layer of metal, typically copper, is deposited onto the circuit traces.

Solder Mask and Silkscreen Printing:A solder mask is applied to protect the circuit traces from oxidation and to prevent solder bridges during assembly. Additionally, a silkscreen printing process is used to add component labels, logos, and other markings on the flexible PCB.

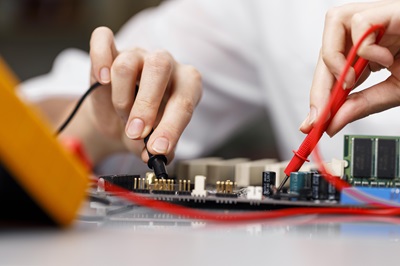

Assembly and Testing:Once the circuit fabrication is complete, components are mounted onto the flexible PCB using automated assembly techniques. The assembled PCB is then subjected to rigorous testing to ensure its functionality and reliability.

Flexibility and Space Efficiency:Flexible PCB circuits offer the advantage of bending and flexing, allowing them to fit into tight spaces and conform to irregular shapes. This flexibility enables the design of compact and lightweight electronic devices.

Increased Reliability:The absence of solder joints and connectors found in rigid PCBs reduces the risk of mechanical failure due to vibration, shock, or thermal stress. Flexible PCBs also exhibit excellent resistance to temperature variations and can withstand extreme environmental conditions.

Improved Signal Integrity:The use of flexible substrates with low dielectric constant and loss tangent results in reduced signal loss and improved signal integrity. This makes flexible PCB circuits suitable for high-speed applications and RF (Radio Frequency) designs.

Design Complexity:Designing flexible PCB circuits requires specialized knowledge and expertise due to the unique considerations involved, such as bend radius, impedance control, and mechanical stress. The complexity of the design process can increase development time and cost.

Manufacturing Constraints:The manufacturing processes for flexible PCB circuits are more intricate compared to rigid PCBs. The handling of flexible substrates and the need for precise alignment during assembly pose challenges that may result in higher production costs.

Cost:Flexible PCB circuits tend to be more expensive than rigid PCBs due to the specialized materials and manufacturing processes involved. However, as the demand for flexible PCBs increases and technology advances, costs are expected to decrease.

Flexible PCB circuits offer numerous advantages, including flexibility, space efficiency, increased reliability, and improved signal integrity. Despite the challenges associated with their manufacturing and design complexity, the benefits they provide make them an attractive choice for various applications in the electronics industry. As technology continues to evolve, the demand for flexible PCB circuits is expected to grow, driving further advancements in their manufacturing processes and reducing costs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.