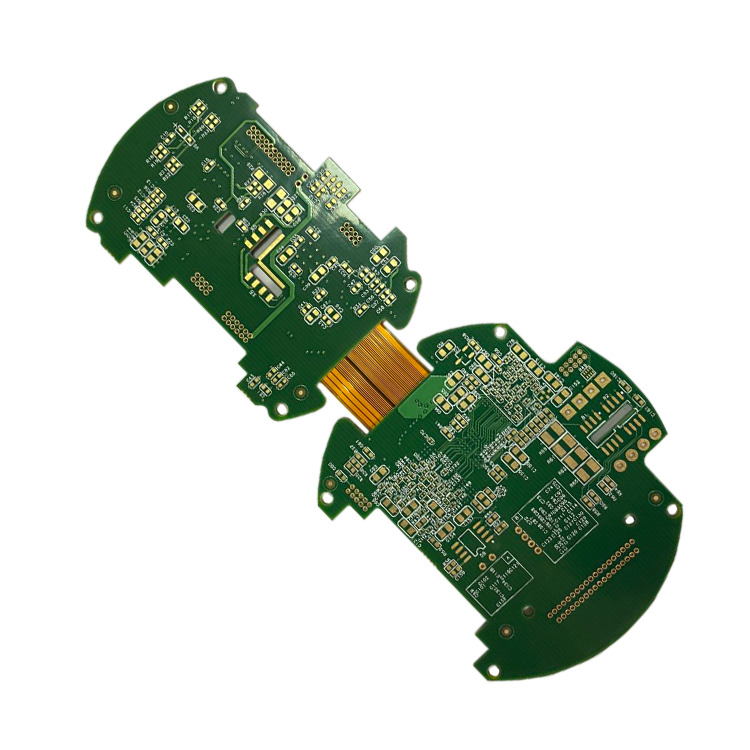

Rigid flex circuit boards are a type of electronic circuit board that has both rigid and flexible components. They are commonly used in applications where space is limited or where the circuit board needs to be able to bend or flex. In this article, we will discuss how to choose and apply rigid flex circuit boards.

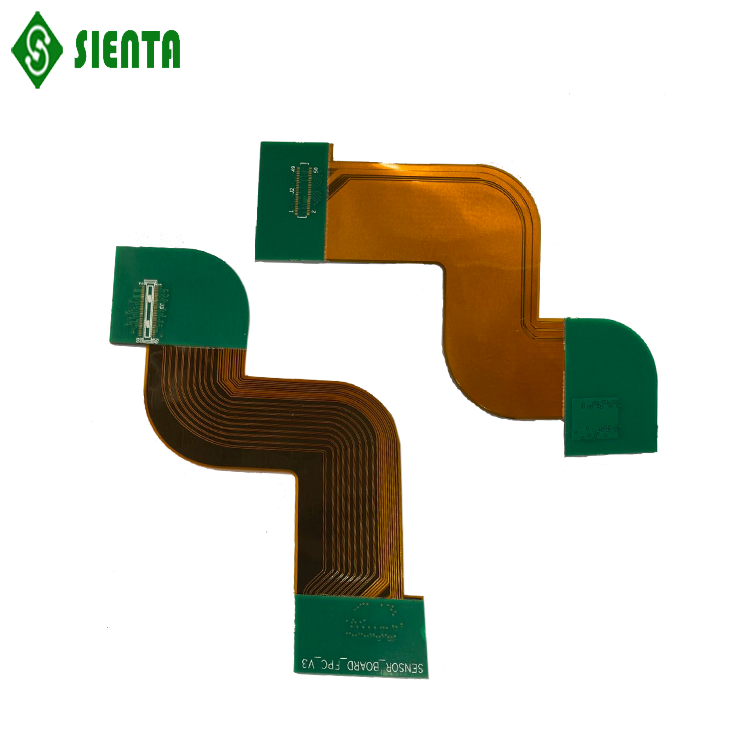

There are two main types of rigid flex circuit boards: single-sided and double-sided. Single-sided rigid flex circuit boards have a single layer of flexible material that is laminated to a rigid layer. Double-sided rigid flex circuit boards have two layers of flexible material that are laminated to a rigid layer.

Single-sided rigid flex circuit boards are typically used in applications where there is limited space and the board needs to be flexible. Double-sided rigid flex circuit boards are used in applications where there is more space and the board needs to be able to bend and flex in multiple directions.

When choosing a rigid flex circuit board, there are several factors to consider. These include the number of layers, the material used, and the thickness of the board.

The number of layers in a rigid flex circuit board will depend on the complexity of the circuit. A simple circuit may only require a single layer, while a more complex circuit may require multiple layers. The number of layers will also affect the cost of the board.

The material used in a rigid flex circuit board will affect its flexibility and durability. The most common materials used are polyimide and polyester. Polyimide is a more expensive material, but it is more durable and can withstand higher temperatures. Polyester is a less expensive material, but it is not as durable and cannot withstand high temperatures.

The thickness of a rigid flex circuit board will depend on the application. A thinner board will be more flexible, but it may not be as durable. A thicker board will be more durable, but it may not be as flexible.

Rigid flex circuit boards are commonly used in applications where space is limited or where the board needs to be able to bend or flex. Some common applications include medical devices, aerospace and defense equipment, and consumer electronics.

Rigid flex circuit boards are commonly used in medical devices because they can be designed to fit into small spaces. They are also durable and can withstand high temperatures and harsh chemicals. Some common medical devices that use rigid flex circuit boards include pacemakers, defibrillators, and insulin pumps.

Rigid flex circuit boards are also commonly used in aerospace and defense equipment. They are durable and can withstand high temperatures and harsh environments. Some common aerospace and defense applications include satellites, missile guidance systems, and aircraft instrumentation.

Rigid flex circuit boards are also used in consumer electronics. They are commonly used in smartphones, tablets, and laptops. They are also used in wearable technology such as smartwatches and fitness trackers.

Rigid flex circuit boards are a versatile type of electronic circuit board that can be used in a variety of applications. When choosing a rigid flex circuit board, it is important to consider the number of layers, the material used, and the thickness of the board. Rigid flex circuit boards are commonly used in medical devices, aerospace and defense equipment, and consumer electronics.

Founded in 2010, Shenzhen SIENTA Industry Co.,Ltd is a leading manufacturer specializing in flexible PCB,rigid-flex PCB and PCB assembly services.Our 12,000 square meter plant is fully equipped with state-of-the-art technology and staffed by over 300 experienced workers and a skilled technical team.

With a monthly production capacity of up to 15,000 square meters, we're dedicated to delivering high-quality products that meet the demands of our customers in the consumer electronics, communication devices, medical equipment, automotive electronics, and other high-tech industries.At SIENTA, we pride ourselves on our commitment to quality control, as demonstrated by our ISO 9001:2015, SGS, ISO14001, ROHS, and IAFT16949 approvals.

Our product range includes 1-12 layer boards, flex circuits, and rigid-flex boards, with a particular emphasis on manufacturing high-precision flexible PCB in 1-10 layers for quick-turn prototypes and mass production.We also offer a complete range of PCB assembly services, from basic through-hole assembly to ultra-fine pitch BGA assembly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.