Printed Circuit Board Assembly (PCBA) stands as a cornerstone process within the realm of electronic device manufacturing, wielding significant influence over the functionality and reliability of a diverse array of electronic products. This comprehensive guide endeavors to delve deeply into the intricacies of PCBA circuit boards, spanning their constituent elements, manufacturing intricacies, and overarching importance within the electronics industry landscape.

PCBA circuit boards comprise a triad of foundational components: a resilient substrate, conductive traces, and an array of electronic components. The substrate, typically fashioned from fiberglass-reinforced epoxy laminate, furnishes a robust scaffold for the board. Conducive traces, predominantly crafted from copper, carve out pathways facilitating the transmission of electrical signals among components. Meanwhile, a spectrum of electronic components, spanning resistors, capacitors, integrated circuits, and connectors, are meticulously mounted onto the board, amalgamating to form a cohesive electronic system.

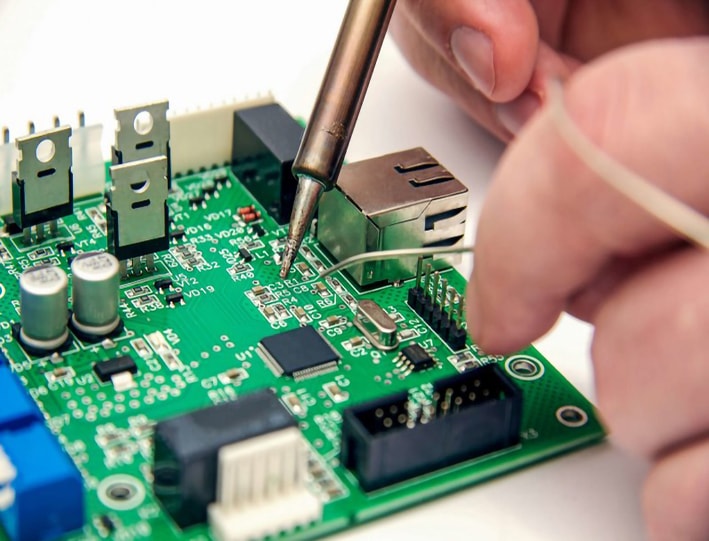

The PCBA manufacturing odyssey unfolds through a sequence of pivotal stages, commencing with PCB fabrication and culminating in exhaustive testing protocols. Initial strides entail the genesis of the bare board through PCB fabrication, closely trailed by the procurement of requisite electronic components. Subsequent phases witness the judicious application of solder paste onto the board, alongside the automated orchestration of component placement. Following this, the board undergoes meticulous soldering procedures to firmly affix the components in place, paving the way for rigorous inspection and testing endeavors aimed at ensuring unwavering quality and functionality.

PCBA circuit boards emerge as linchpins in dictating the operational prowess and efficacy of electronic devices. By furnishing indispensable electrical connections and robust mechanical support to electronic components, these boards empower devices to function seamlessly as intended. The criticality of upholding impeccable quality and reliability standards for PCBA circuit boards cannot be overstated, as these factors bear direct sway over the overarching performance, longevity, and safety of electronic products.

Attaining pinnacle performance and manufacturability hinges upon the meticulous execution of effective PCBA circuit board design paradigms. Paramount considerations encompass strategic component placement, judicious trace routing, adept thermal management strategies, and the preservation of signal integrity. Embracing the principles of Design for Manufacturing (DFM) and Design for Testability (DFT) emerges as imperative, affording avenues for streamlining manufacturing and testing workflows whilst bolstering overall efficacy.

PCBA circuit boards find ubiquitous utility across a panoply of industries, ranging from consumer electronics to automotive, telecommunications, medical devices, aerospace, and industrial domains. Each sector imposes unique exigencies and standards upon PCBA circuit boards, necessitating bespoke design and manufacturing considerations tailored to meet specialized requisites.

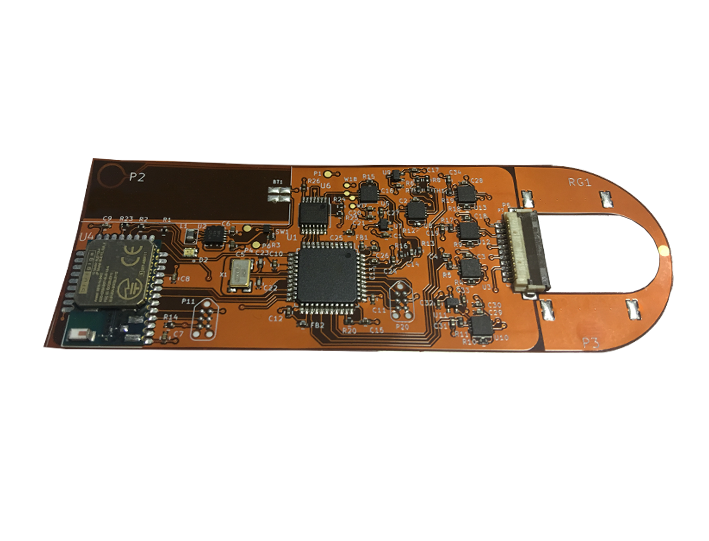

The evolutionary trajectory of PCBA technology continues unabated, propelled by pioneering innovations spanning materials, manufacturing methodologies, and component miniaturization endeavors. Cutting-edge advancements, including flexible PCBs, rigid-flex PCBs, and high-density interconnect (HDI) boards, have ushered in an era characterized by compact yet high-performance electronic designs. Furthermore, the seamless integration of surface-mount technology (SMT), automation, and advanced inspection techniques has engendered heightened efficiency and quality benchmarks within PCBA manufacturing ecosystems.

The bedrock of reliability and functionality within PCBA manufacturing realms is fortified through stringent quality control and testing imperatives. Employing a gamut of inspection methodologies, encompassing automated optical inspection (AOI), X-ray scrutiny, and functional testing protocols, facilitates the early detection of defects, validation of component placement, and verification of electrical functionality. Such rigorous testing regimens serve as bulwarks against potential anomalies, ensuring that final products are primed for deployment with unwavering reliability and performance prowess.

PCBA circuit boards stand resolute as linchpins within the electronics industry, underpinning the very fabric of electronic devices. Acquainting oneself with the core tenets of PCBA circuit boards, spanning their constituent elements, manufacturing intricacies, design considerations, industrial applications, technological advancements, and quality control protocols, assumes paramount significance for stakeholders across the electronics supply chain. As the march of technology presses onward, the indispensable role of PCBA circuit boards in sculpting the trajectory of electronic devices and systems remains unassailable.

By continuing to use the site you agree to our privacy policy Terms and Conditions.