News

Site Editor

Site

/uploads/image/667d0e0257f45.png

Site

/uploads/image/667d0e0257f45.png

Unveiling the Secrets of FPC Stiffener: How Different Materials Bestow Unique Properties on Flexible Printed Circuits

Views: 1469

Author: Site Editor

Publish Time: 2024-11-21

Origin: Site

In

Flexible Printed Circuit (

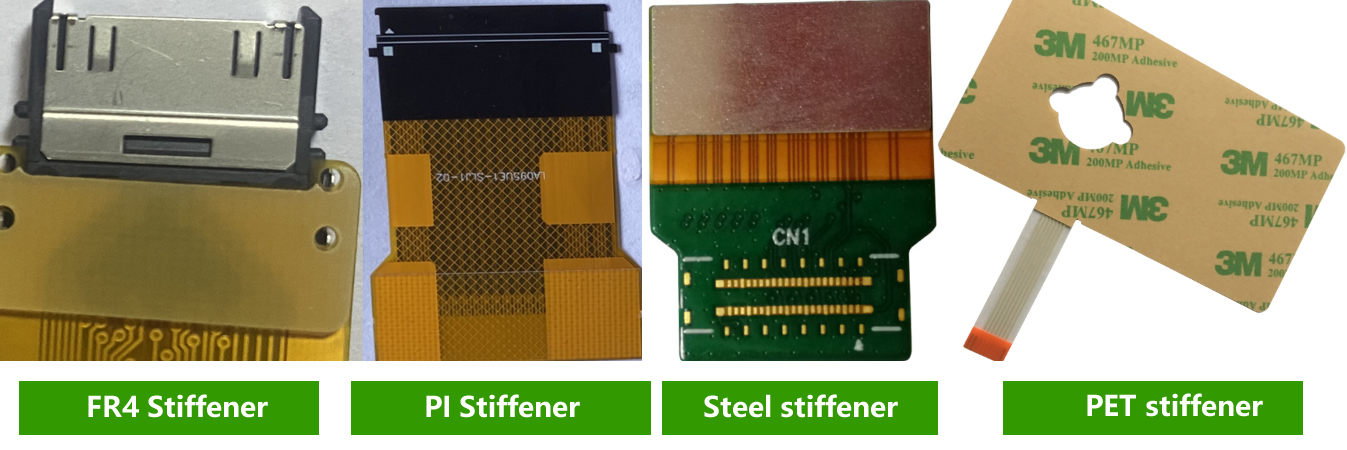

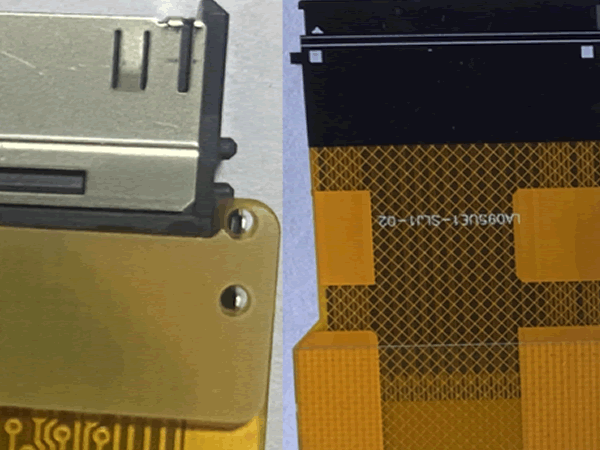

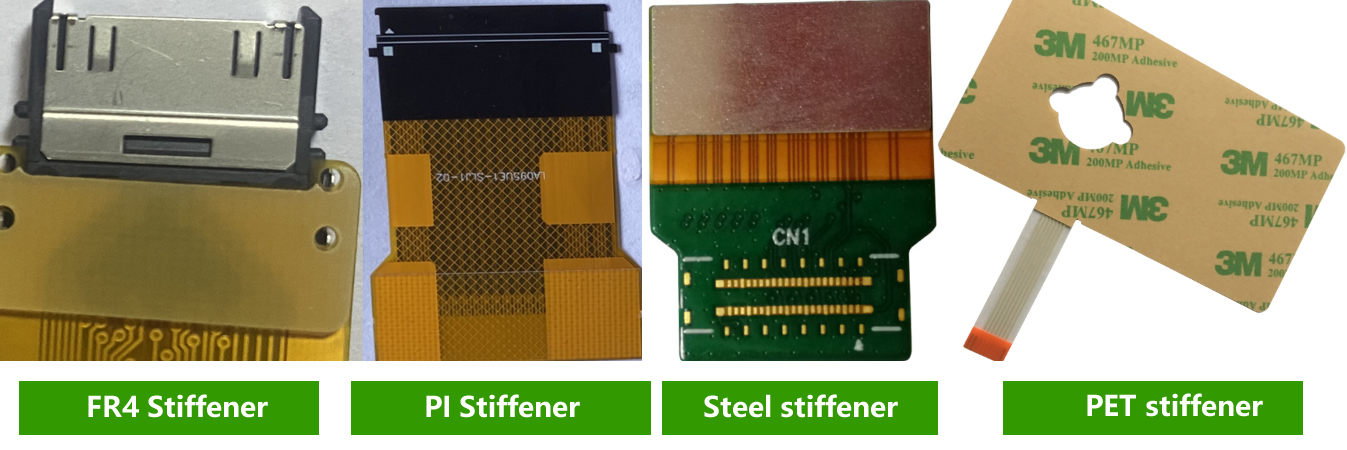

FPC), different materials of reinforcement materials each play a key role to meet the performance requirements of FPC in different application scenarios. The following stiffener materials are commonly used by Sienta, including steel stiffener , PI stiffener , FR4 stiffener and PET stiffener.

|

Types

|

Material

:

|

Application

|

Characteristics

|

|

Steel

Stiffeners

|

Stainless steel or other alloy steel.

|

Used in areas requiring high strength and hardness, typically in connector parts or where bending and deformation need to be prevented.

|

High strength, high hardness, wear-resistant, but heavier, which affects the overall flexibility of the FPC

|

|

PI

Stiffeners

|

Polyimide

|

Widely used in areas that need a certain hardness but should retain some flexibility

|

Lightweight,high-temperature resistant, good electrical insulation properties, enhances the mechanical strength of the FPC while maintaining some flexibility.

|

|

FR4

Stiffener

|

Fiberglass epoxy (FR4).

|

Usually used in connector areas or other places that require stability

|

High strength, good dimensional stability, high-temperature resistant, but heavier and harder than PI

stiffener

|

|

PET

Stiffener

|

Polyester

|

Used in areas that need increased mechanical strength but have low temperature requirements.

|

Low cost, easy processing, but lower high-temperature performance and electrical properties compared to PI and FR4.

|

Performance Characteristics

·

Mechanical Strength

:

Stiffener

materials significantly enhance the mechanical strength of FPCs, preventing breakage or deformation due to excessive bending and stretching.

·

Flexibility and Rigidity Balance

: Different

stiffener

materials offer varying degrees of rigidity. Choosing the appropriate

stiffener

material can provide necessary rigidity while maintaining some flexibility of the FPC.

·

Thermal Stability

: In high-temperature environments, PI and FR4 materials offer superior

stiffener

performance, suitable for applications requiring high thermal stability.

·

Electrical Insulation Performance

: PI

stiffener

materials have excellent electrical insulation properties, suitable for high voltage or high electrical performance applications.

·

Weight Impact

: Different

stiffener

materials affect the overall weight of the FPC. Steel plates are the heaviest, while PI and adhesive

stiffener

s are relatively lightweight.

·

Processability

: The ease of processing

stiffener

materials varies. Adhesive and PET

stiffener

are easier to process, while steel plates and FR4 require more complex processing.

Different materials of stiffener in the FPC each play an irreplaceable role, they provide mechanical support, enhance circuit performance, improve heat resistance and stability, etc., to ensure that the FPC in a variety of application scenarios, reliable operation. When selecting stiffener materials, it is necessary to consider the FPC application environment, performance requirements and cost and other factors in order to select the most appropriate stiffener materials. As an FPC manufacturer, Sienta is committed to providing high-quality FPC solutions to help customers get the best performance in various applications. If you have any questions about our products or services, please feel free to contact us.