The PCBA industry serves as the backbone of modern electronics, driving innovation and connectivity across diverse sectors. In the current industry landscape, a multifaceted analysis reveals critical aspects that shape its trajectory.

The market size of the PCBA manufacturing industry has witnessed significant growth in recent years. With the continuous increase in demand for electronic devices, the market size of PCBA has expanded accordingly. The prosperity of this industry is primarily driven by the sustained development in areas such as smartphones, IoT devices, and automotive electronics.

The PCBA manufacturing industry involves a multitude of participants, ranging from large multinational corporations to small and medium-sized manufacturers. Key participants typically include Electronic Manufacturing Services (EMS) providers, PCBA manufacturers, and Original Design Manufacturers (ODM). Major companies like Foxconn, OFilm, and others hold significant market shares globally, while smaller enterprises may focus on specific niches or market segments.

PCBA manufacturing is a fiercely competitive industry where participants vie for market share and technological advantages. Competition among manufacturers is predominantly centered around factors such as production efficiency, quality control, innovation capabilities, and cost management. Globalization has necessitated manufacturers to adapt to changes in the global supply chain and face competition in international markets.

The future trends of the PCBA manufacturing industry are influenced by various factors. The continuous development of technologies such as the Internet of Things (IoT), 5G, and artificial intelligence will present both opportunities and challenges for PCBA manufacturing. Trends like smart manufacturing, automation, and sustainability will further shape the PCBA manufacturing landscape. Additionally, the rise of emerging markets and consumer demand for innovation in electronic products will impact the industry's direction.

PCBA design is a meticulous process that forms the foundation of electronic devices. Delving into its complexities reveals a world where the synergy of aesthetics and functionality is finely balanced, and every detail holds significance.

At the heart of PCBA design lies the schematic, a visual representation of the circuit's architecture. Schematic design serves as the blueprint, illustrating the interconnection of components and their functions. Designers carefully craft schematics, considering the flow of signals, power distribution, and the overall functionality of the circuit.

The placement of components on the PCB is a delicate dance between efficiency and practicality. Designers strategically position components to optimize signal flow, minimize interference, and enhance the overall performance of the circuit. The spatial arrangement considers factors such as thermal management, signal integrity, and accessibility for manufacturing processes.

In addition, the layout of the PCB involves the physical arrangement of components, traces, and other elements on the board. It is a careful consideration of space, form, and function. Aesthetic considerations come into play as the layout should not only meet functional requirements but also be visually coherent. The placement of components affects the efficiency of the PCB, and a well-thought-out layout contributes to the ease of manufacturing, testing, and later stages of the production process.

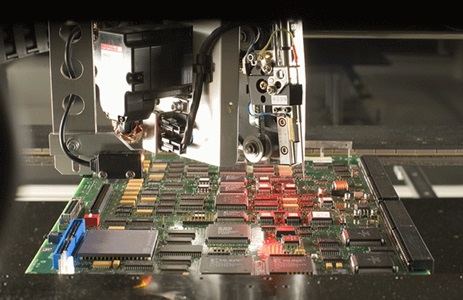

PCBA (Printed Circuit Board Assembly) fabrication involves a series of techniques to manufacture the printed circuit board (PCB) and assemble electronic components onto it. These techniques ensure the precise creation of the PCB and the reliable attachment of components.

Surface Mount Technology is a key technique for mounting electronic components onto the PCB. It involves placing miniature components directly onto the surface of the board, eliminating the need for leads or holes. SMT enhances space utilization and enables the assembly of smaller and lighter electronic devices.

While SMT is prevalent, some components, particularly connectors and larger devices, may still use Through-Hole Technology. This involves inserting component leads through drilled holes in the PCB and soldering them on the opposite side. THT provides mechanical strength and stability to larger components.

Soldering is the process of joining components to the PCB using solder. Various soldering techniques include wave soldering for through-hole components and reflow soldering for SMT components. Precision in soldering is crucial for forming reliable connections and ensuring the durability of the assembly.

After completion of component mounting and soldering, the PCBA enters the quality control and testing phase. This includes functional testing through automated test equipment, checking the quality of the soldering and verifying the performance of the circuit. Any potential defects need to be promptly detected and repaired at this stage to ensure the quality of the final product.

In the current market segments, the military, industrial, medical, automotive or consumer electronics industries are experiencing tremendous innovation and growth.

With the upgradation of technology, processes and procedures have been modified through the adoption of industry SMT chip processing equipment, surface mount technology, one-stop PCBA packages, reverse engineering of electronic products and other assembly services. This has made Sienta one of the mainstays in catering for a wide range of contract manufacturing services through advanced electronics and layout solutions for their PCB needs.

Technological advancements play a key role in PCBA manufacturing technology. Advanced automation equipment and smart manufacturing techniques have increased productivity and reduced human error in the manufacturing process. Precision CNC machine tools and high-resolution lithography improve the accuracy of the manufacturing process, ensuring the quality and performance of the board.

Sienta provides professional PCB Assembly services with over a decade of expertise. Our precise processes comply with internationally accepted quality standards including ISO-9001:2015, RoHS , IATF16949, ISO13485, ISO14000 and more. Our superior engineering capabilities mean that every board meets your exact requirements and specifications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.