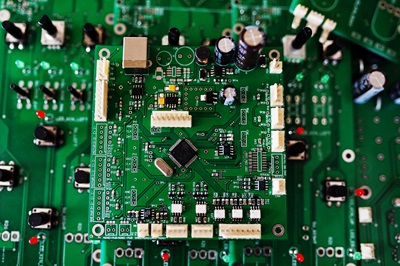

In the dynamic realm of electronics, efficiency in Printed Circuit Board Assembly (PCBA) manufacturing isn't merely a target; it's an imperative. This article embarks on a comprehensive journey through the various stages of PCBA, uncovering the intricacies pivotal for attaining efficiency from the inception of design to the final deployment of circuit boards.

Design Precision for Enhanced Efficiency:

At the heart of efficient PCBA lies the design phase, where precision not only ensures functionality but also lays the groundwork for a streamlined production process. Engineers must meticulously craft layouts optimizing component placement, considering factors ranging from signal integrity to thermal management.

Advanced CAD Tools: The Architects of Success:

The adoption of advanced Computer-Aided Design (CAD) tools is paramount. These tools provide engineers with a visual platform to intricately explore PCB layouts, enabling them to anticipate potential manufacturing challenges and make informed decisions early in the process, thereby saving time and resources.

Selecting the Right Substrates:

Material selection emerges as a foundational aspect of efficient PCBA. The choice of substrates influences not only electrical performance but also thermal conductivity and overall reliability. Engineers must meticulously evaluate the application environment, project requirements, and budget constraints to make informed decisions.

Strategic Component Sourcing:

Efficient PCBA extends to strategic component sourcing. Cultivating relationships with dependable suppliers ensures a consistent supply of quality components. The accessibility of components plays a pivotal role in mitigating delays, a critical factor in maintaining a seamless manufacturing workflow.

The Rise of Automated Manufacturing:

Automation stands as a linchpin for achieving efficiency in PCBA. Automated assembly lines offer myriad benefits, including reduced error margins, heightened precision, and accelerated production. Robotic soldering, pick-and-place machines, and automated inspection systems collectively contribute to a seamless, error-free assembly process.

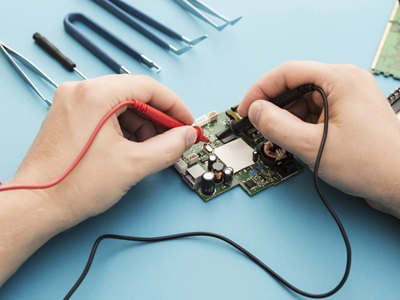

Quality Control in Automation:

While automation expedites production, stringent quality control measures are imperative. Regular inspections and testing at various assembly stages ensure that each PCB adheres to the highest standards. Automated inspection tools play a pivotal role in identifying defects and anomalies, preventing subpar products from advancing further in the manufacturing pipeline.

Streamlined Deployment Processes:

Efficiency in PCBA transcends the production floor, extending to deployment strategies. Implementing streamlined deployment processes, including effective testing methodologies and packaging solutions, ensures that end products reach the market with minimal lead time.

Feedback Loops for Continuous Improvement:

Establishing feedback loops connecting deployment experiences back to the design phase fosters a cycle of continuous improvement. Real-world performance data informs future design iterations, enabling manufacturers to adapt and enhance their PCBA processes based on practical outcomes.

Unlocking the secrets of efficient PCBA manufacturing demands a holistic approach spanning meticulous design practices to strategic deployment strategies. By comprehending the intricacies of each phase and embracing technological advancements, manufacturers can navigate the complexities of PCBA with precision, ensuring the delivery of reliable and high-performance electronic products to the market. This holistic approach not only enhances efficiency but also establishes a foundation for innovation and adaptability in the ever-evolving landscape of electronic manufacturing.

By continuing to use the site you agree to our privacy policy Terms and Conditions.