News

Site Editor

Site

/uploads/image/667d0e0257f45.png

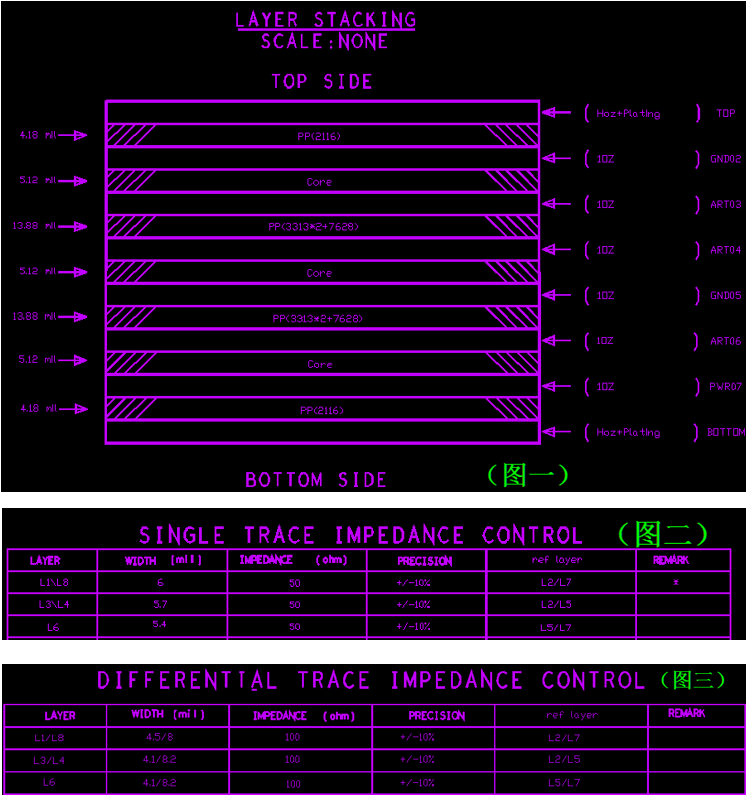

Signal lines that need to be impeded should be set strictly in accordance with the line width and line spacing calculated by the stackup.

Site

/uploads/image/667d0e0257f45.png

Signal lines that need to be impeded should be set strictly in accordance with the line width and line spacing calculated by the stackup.

How to Set Line Width and Distance when Doing PCB Design?

Views: 1750

Author: Site Editor

Publish Time: 2023-06-20

Origin: Site