The arena of electronic manufacturing emerges as a convergence of innovation and precision, with the crux of its essence lying in the meticulous craft of producing high-caliber Printed Circuit Board Assemblies (PCBAs). These intricate electronic ensembles serve as the backbone of contemporary devices, necessitating a nuanced comprehension of the multifaceted journey from conceptual design to intricate assembly. This comprehensive guide endeavors to unravel the layers of complexity inherent in fashioning top-tier PCBAs, illuminating the pivotal considerations that engineers and manufacturers must seamlessly integrate into their pursuit of excellence.

The prelude to PCBA excellence unfolds with the symphony of design, transcending mere aesthetics to delve into the realm of functionality. Engineers embark on a voyage where the layout and placement of components serve as the melodic notes and harmonious chords that underpin the final product's seamless functionality. Employing cutting-edge design tools transcends preference; it becomes an imperative enabling the orchestration of elements that optimize signal integrity, adeptly navigate thermal landscapes, and shield against electromagnetic interference.

The essence of a PCBA lies in the discerning selection of materials, an intricate alchemy aimed at ensuring compatibility with diverse environmental exigencies. Engineers navigate a labyrinth of choices, meticulously selecting each component for its resilience to the rigors of varied conditions, thereby guaranteeing the longevity and stability of the PCBA. Meanwhile, trace routing assumes the mantle of an intricate dance of electrons, demanding precision to mitigate signal loss, obviate cross-talk, and maintain a delicate equilibrium to forestall short circuits.

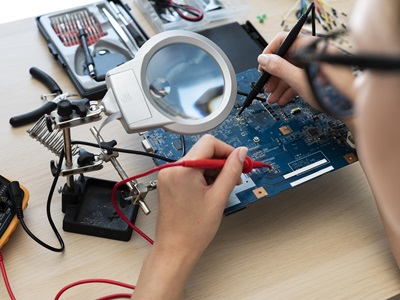

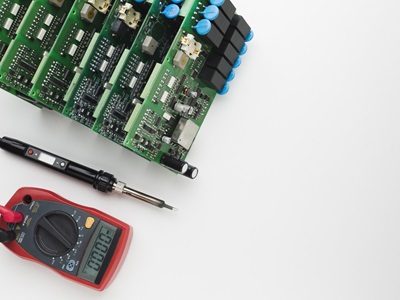

As the design metamorphoses into tangible reality during the assembly phase, the crucible of craftsmanship takes center stage. The choice between Surface Mount Technology (SMT) and Through-Hole Technology (THT) mirrors the selection of brushstrokes on a canvas. The precision of reflow soldering for SMT components or the artisanal touch of hand soldering for THT components emerges as an art form that shapes the destiny of the PCBA. A symphony of state-of-the-art equipment and skilled artisans becomes the crucible for crafting solder joints that resonate with unwavering reliability.

In the sanctum of manufacturing, quality control emerges as the vigilant sentinel, safeguarding the sanctity of high-quality PCBAs. Automated Optical Inspection (AOI) and X-ray scrutiny assume the mantle of discerning sentinels, meticulously ferreting out soldering defects and scrutinizing component alignments with exacting precision. Functional testing, akin to a grand performance, meticulously evaluates the PCBA's aptitude to seamlessly execute its designated functions. Only through such exhaustive evaluation can manufacturers bestow upon the world PCBAs that stand as exemplars of reliability and performance.

The journey of the PCBA extends beyond the sterile precincts of manufacturing to confront the crucible of real-world environmental challenges. Engineers navigate temperature fluctuations, humidity, and exposure to corrosive elements with strategic acumen. Conformal coatings emerge as the resilient armor, fortifying the delicate electronics against nature's caprices. The integration of Design for Manufacturability (DFM) principles not only ensures streamlined production but also fortifies the PCBA against the diverse challenges presented by the ever-evolving environment.

In the expansive vista of electronic manufacturing, attaining high-quality PCBA parallels the endeavor of navigating a labyrinthine tapestry of innovation, precision, and artistry. This intricate journey transcends the mere construction of a circuit; it encompasses the delicate art of crafting a magnum opus that reverberates throughout the reliability and performance of electronic devices. As engineers and manufacturers delve into the core considerations, they embark on a quest to sculpt not just a functional PCBA but a lasting testament to excellence, resilience, and longevity in the perpetually evolving realm of electronic craftsmanship.

By continuing to use the site you agree to our privacy policy Terms and Conditions.