At the heart of flexible printed circuits (FPCs) lies the base material, known as Flexible Copper Clad Laminate (FCCL), comprising Copper combined with Polyimide (PI) or with an additional adhesive layer (AD) and PI. This article delves into the significance of copper selection in FPC fabrication, focusing on Electrodeposited Copper Foil (ED Copper) and Rolled Annealed Copper Foil (RA Copper), elucidating their differences and applications.

ED Copper is produced through an electrolysis process, wherein a copper sulfate (CuSO4) solution is electrolyzed to deposit copper onto spinning cathode rolls. Conversely, RA Copper is derived from high-purity copper (>99.98%) through pressure processes, resulting in varying copper thicknesses.

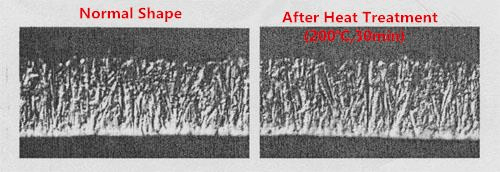

ED Copper (Electrodeposited Copper Foil)

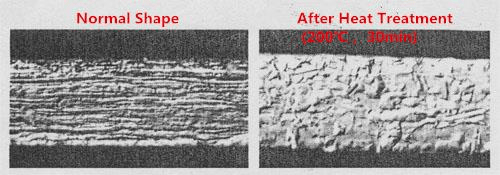

RA Cooper (Rolled Annealed Copper Foil)

The distinct manufacturing methods yield contrasting performance characteristics:

Conductivity: ED Copper boasts superior electrical conductivity compared to RA Copper, owing to its refined deposition process.

Extensibility: RA Copper exhibits greater extensibility, making it more suitable for applications requiring frequent bending and flexing.

The choice between RA Copper and ED Copper hinges on the specific requirements of the application:

For flexible boards requiring extensive bending capabilities, such as wearable electronics or flexible displays, RA Copper is the preferred choice due to its superior flexibility and resilience.

Conversely, applications demanding high electrical performance, such as high-speed data transmission or RF circuits, benefit from the enhanced conductivity of ED Copper.

The selection of copper in FPC fabrication significantly influences the performance and suitability of the final product. By understanding the distinctions between ED Copper and RA Copper in terms of manufacturing methods, performance attributes, and applications, manufacturers can make informed decisions to meet the diverse needs of their FPC designs. Whether prioritizing flexibility or electrical performance, selecting the appropriate copper variant is essential for achieving optimal results in FPC fabrication.

By continuing to use the site you agree to our privacy policy Terms and Conditions.