Technology

Surface Treatment

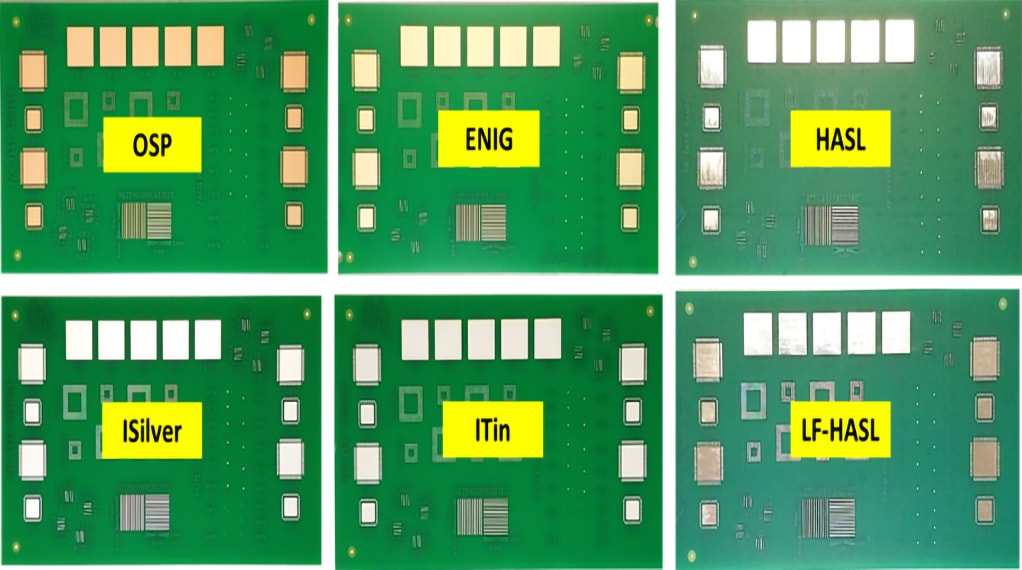

Surface Treatments in the PCB Industry

In the PCB industry, surface treatments play a crucial role in providing protection and enhancing the performance of printed circuit boards. Various methods are employed to treat the surface of PCBs, ensuring optimal functionality and reliability. This article will explore several commonly used surface treatments, including HASL,immersion gold,immersion tin,immersion sliver,flash gold,OSP.

Hot Air Solder Leveling (HASL)

HASL, also known as solder leveling, is a common surface treatment method where a molten tin-lead alloy is applied to the entire surface of the PCB, followed by a hot air leveling process. HASL provides good solderability and corrosion resistance, making it suitable for general-purpose applications.

Immersion Gold

Immersion gold is a popular surface treatment method that involves the electrochemical deposition of a thin layer of gold onto the PCB's surface. Immersion gold provides exceptional conductivity, corrosion resistance, and solderability. It is widely utilized in high-reliability and high-frequency applications, ensuring reliable electrical connections.

Immersion Tin

Immersion tin , also known as tin coating, is a widely used surface treatment in the PCB industry. It involves the electroplating of a thin layer of tin onto the PCB's surface. Tin plating offers excellent solderability and corrosion resistance, facilitating reliable solder joints during the assembly process. It is commonly employed in both surface mount technology (SMT) and conventional applications.

Immersion Silver

Immersion silver involves the deposition of a layer of silver onto the PCB's surface. Silver exhibits excellent conductivity and corrosion resistance, making it ideal for high-frequency applications and demanding electrical connections.

Flash Gold

Flash gold is an electrochemical process used to deposit various metals onto the PCB's surface. It offers versatility in selecting metals such as nickel, copper, or chromium, based on the desired properties and performance requirements. Flash gold enhances conductivity, improves corrosion resistance, and provides protection to the underlying materials.

OSP

OSP is an organic solderability preservative that forms a protective layer on the surface of the PCB. It provides corrosion resistance and solderability, ensuring reliable solder joints. OSP is suitable for SMT applications, where environmental friendliness and surface flatness are essential considerations.

In the PCB industry, surface treatments such as HASL,immersion gold,immersion tin,immersion sliver,flash gold,OSP are utilized to enhance the performance and reliability of printed circuit boards. Each method offers unique advantages, ensuring optimal functionality and protection in various applications. The selection of a specific surface treatment depends on the requirements, environment, and reliability standards of the PCB.